Steel Mezzanines

When it comes to increasing space, it is more economical to building up rather than to expanding outward. Mezzanines are the most common solution for building additional space inwards. A mezzanine is an intermediate floor inside a building, usually with direct access from the inside of the building.

There are a few different types of mezzanine construction, depending on the size and application. To ensure the right solution for your needs, you need to understand the variety of structural options and decking types available.

Cold rolled refers to the method of forming sheet metal into a c-channel to use as the framework of the mezzanine floor.

Cold-rolled material is much lighter than structural steel and therefore easier to handle. It can also be pre-galvanized; offering a substantial savings over painted, hot-dipped galvanized mezzanines.

Cold rolled sections are generally used as a primary or secondary beam member rather than column members.

The major disadvantages of cold-rolled mezzanines is the very limited column spacing (usually 3-4 meters max) and the inability to reach the high live loads or heavily concentrated point loads accomplished with hot rolled mezzanine systems.

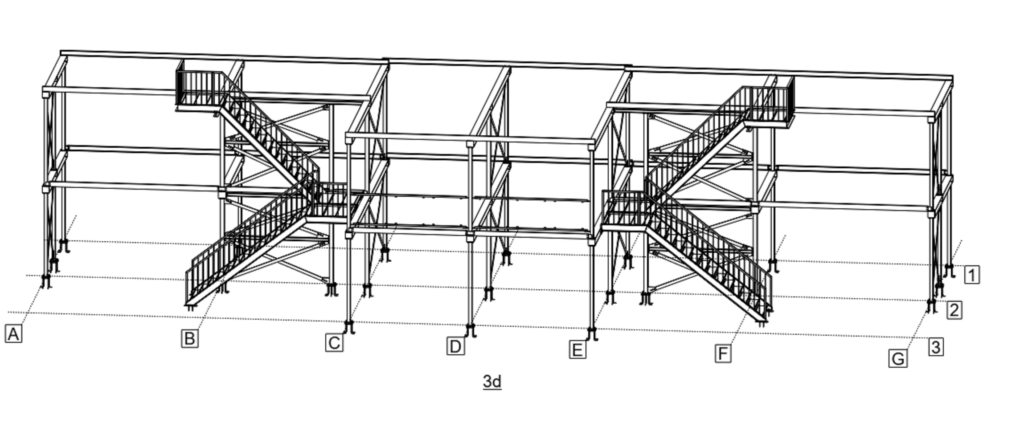

Structural steel mezzanines are constructed of structural I beams, which connect to tubular columns or I-beam columns to form a primary frame.

The greatest benefit of structural steel is allowing bigger column spacing. Column spacing can increase up to 8 meters without compromising the dead and live loads on the mezzanine floor.

The greatest benefit of structural steel is allowing bigger column spacing. Column spacing can increase up to 8 meters without compromising the dead and live loads on the mezzanine floor.

This means more material can be stored in a smaller area ⎯ with more space for manoeuvrability underneath.

Your mezzanine does not depend on the building for support and can be used as a totally freestanding structure or can be combined with your existing equipment.

Our mezzanine floors are individually designed and engineered to suit your specific needs.

Flooring or Decking Type

Since the type of mezzanine decking you choose will be determined by a variety of circumstances, you have a lot of options when it comes to designing your flooring system.

Whether you’re establishing an office and need a deck to support the building’s visual appeal, storing large goods and require a reinforced material to offer adequate support, or anything else, the correct decking will ensure that your floor is perfectly finished.

Tekmetsan, as experts in this field, would be delighted to assist. We’ve got you covered on everything from the suitability of mezzanine decking to which materials look best.

The most durable type of mezzanine decking is concrete. Concrete should be utilised in high-capacity industrial and military applications where the mezzanine is considered permanent since it has a high point load and negligible noise transmission through the deck.

Steel decking comes with a pour stop that allows you to pour up to 15cm of concrete.

In the waste management, mining, and food service industries, steel grating, also known as bar grating or press-locked grating, is a popular alternative.

In the waste management, mining, and food service industries, steel grating, also known as bar grating or press-locked grating, is a popular alternative.

Air, light, heat, and fluids may all pass through the deck surface thanks to steel grating. It’s powerful, long-lasting, and almost maintenance-free.

Most economical selection for general storage and office applications is the OSB flooring. OSB provides good resistance to foot traffic and can handle random wheel loads up to 150 kg.

Produced from hot-rolled steel, alongside its structural configuration made up of an evenly distributed raised pattern, our chequered plate flooring type is extremely robust and durable as well as anti-slip as standard.

Conclusion

Our mezzanine floors are individually designed and engineered to suit your specific needs.

• Maximise existing floor space into profitable rentable areas

• Increase net rentable areas by utilising full building heights

• Fully engineered and certified

• Metal fabricated stairs and Balustrades