Common Metal Building Terminology

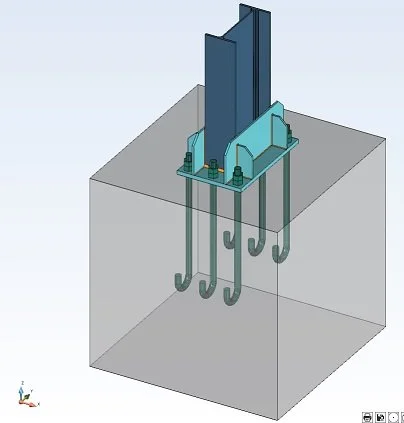

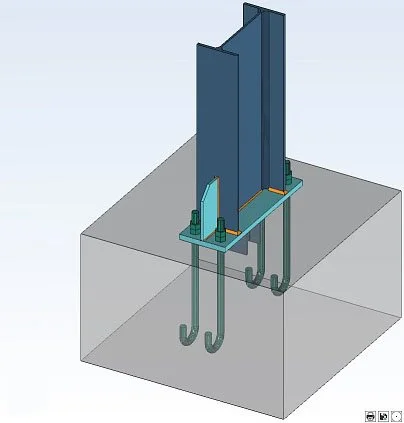

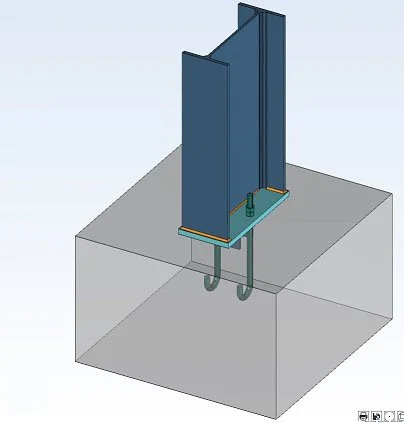

Anchor Bolts

The bolts or rods that fasten components to the foundation or other support. Anchor bolts are usually set in concrete, but they may also be drilled and then set with an epoxy.

Approval Drawings

Product drawings sent to the customer to verify the dimensions and design. These drawings are also used to verify the services and materials the manufacturer will provide.

Bay

The horizontal space between the main frames or primary supporting members.

A structural steel system with rafter beams that are supported by columns.

Bracing

Rods, cables and angles used in the plane of the walls and roof for the purpose of transferring loads to the foundation.

Clear Span

Describes a building with no internal supports. This makes the entire space under the roof usable.

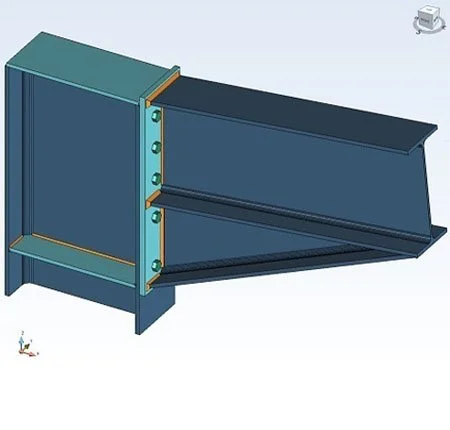

Clip

A metal fastener that holds a component or panel in place.

Corner Column

Corner columns are usually “C” shaped and are placed along the corner of a bearing frame endwall.

Curtain Wall

These are perimeter wall panels that only carry their own weight.

Dead Load

Describes the weight of the structure as well as any permanent stationary loads.

Deck

A structural surface in which the insulation, roofing or waterproofing system is applied.

Eave

A line that runs along the sidewall. Eaves are formed by the intersection of the wall panels and the roof.

Eave Height

Refers to the distance between the finished floor and the top of the eave strut. The roof panel height is not included in the eave height.

Eave Strut

A structural member located at the eave. The strut supports the wall and roof panels.

Endwall

The exterior wall that runs parallel to the building’s primary frame.

Envelope

Separates the interior and exterior of the building.

Screws or clips used to attach panels to frame members or other panels.

Flashing

A piece of metal that seals edgings along walls, drains, expansion joints or gravel stops.

Footing

A mat or pad, usually made of concrete, that sits underneath a wall, column or other structural member. The footing distributes loads from the member onto the supporting soil.

The substructure that the building rests on. Foundations are typically made of concrete and has footings for columns to rest on.

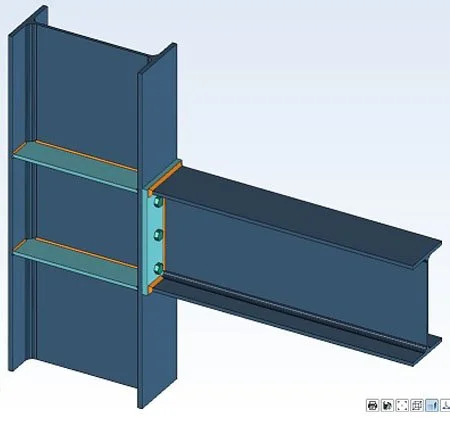

Frame

A series of columns and rafters that support the secondary framing.

Framed Opening

An opening in a wall formed by flashing and framing members.

Gable

A triangular area of the building’s endwall that sits above the eave height and below the sloping roof.

Girt

A horizontal structural member that attaches to endwall or sidewall columns. Wall coverings are attached to girts and supported horizontally.

Haunch

Sometimes referred to as “Knee.” The haunch is the roof’s lowest point, and it’s designed to handle the stress of where columns and rafters connect.

Joist

Open web beams used for support in the floor or roof of a mezzanine. They can effectively carry large loads or span large distances.

Live Load

A varying or moving load that the structure supports. A roof live load, for example, usually refers to snow load.

Main Framing

Consists of steel frames that support secondary framing members, such as purlins, eave struts and girts.

Sandwich Panel

Insulation panels cover the roof and wall areas.

Pier

Concrete structures that transfer a vertical load from a column’s base to a footing.

Pitch

A slope or incline measured by percent or degrees, or by the rise and run ratio.

Purlin

A horizontal structural member in the roof that supports sheeting and is supported by the building’s primary framing.

Rake

Where the plane of the endwall and the plane of the roof intersect.

Rafter

A primary structural member that runs from haunch to apex. Rafters are any beams used in the main framing to support purlins.

Ridge

The highest point of the roof; a horizontal line that runs along the length of the building.

Secondary Framing

Structural members that carry loads from the surface of the building to the primary framing members. Girts and purlins are both considered secondary framing.

Self-Tapping Screws

A special fastener that taps, or creates, threads inside a predrilled hole.

Standing Seam

A standing seam is an upturned ribbed that has a watertight seal.

Trim

Used to finish a building. Trim is typically applied to framed openings and where surfaces intersect. Light gauge metal is used for trim.

Truss

Consists of three or more members. Each member carries a tension or compression force, therefore acting as a beam.

Wall Covering

Exterior wall panels or sheets and their attachments, trim and sealants.

Wind Load

Refers to the load from wind blowing in a horizontal direction.

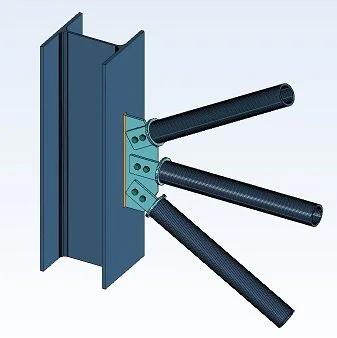

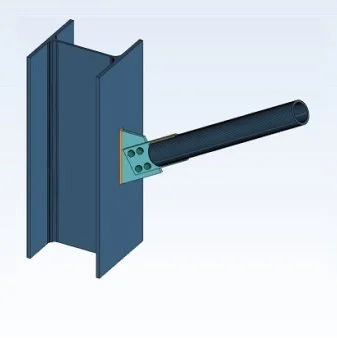

X-Bracing

Provides additional strength and bracing through the use of rods, cables and sometimes, angles.

6. Weld Quality Management

6. Weld Quality Management

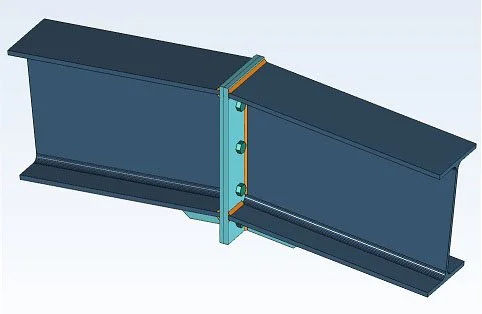

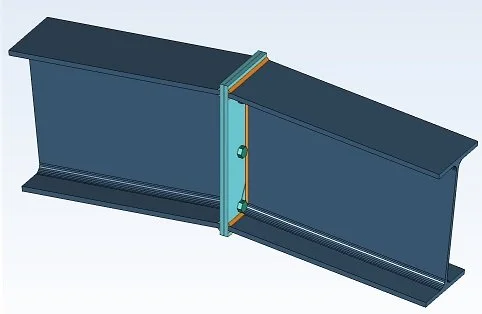

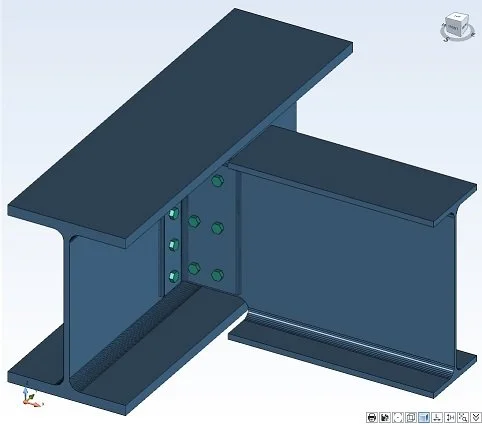

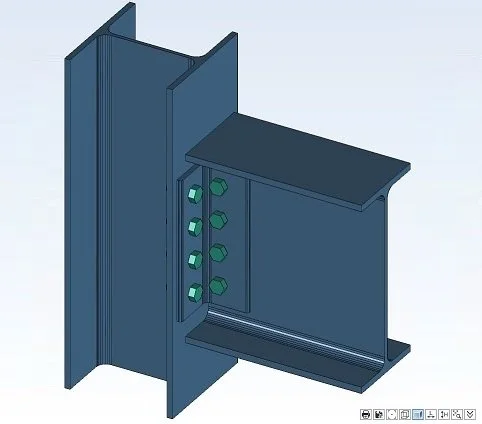

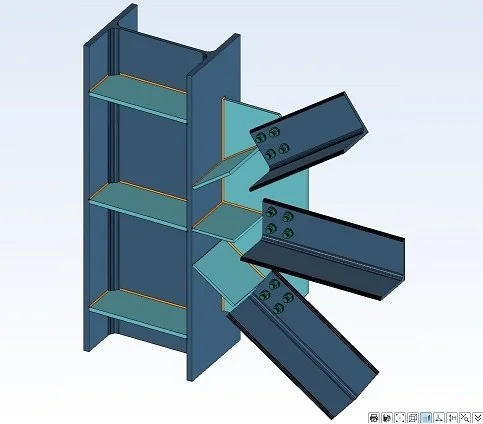

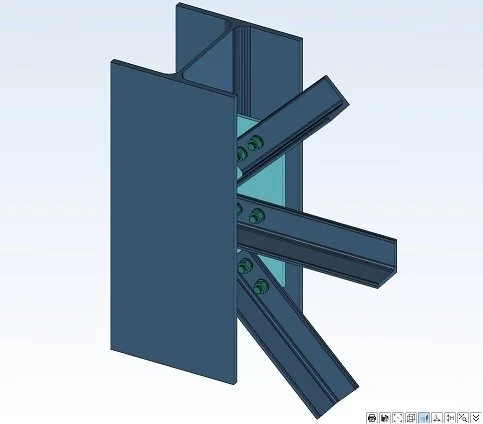

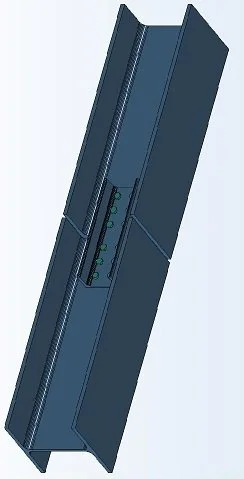

Heavy hex bolts are characterised by a distinct hexagonal head, making them larger and thicker than standard hex bolts. Heavy hex structural bolts are ideal for steel-to-steel structural connections. They are typically very short. The A325 and A490 specifications are not intended for general applications, including anchor bolts. A449 for A325 and A354 grade BD for A490 are a more suitable choice in these applications.

Heavy hex bolts are characterised by a distinct hexagonal head, making them larger and thicker than standard hex bolts. Heavy hex structural bolts are ideal for steel-to-steel structural connections. They are typically very short. The A325 and A490 specifications are not intended for general applications, including anchor bolts. A449 for A325 and A354 grade BD for A490 are a more suitable choice in these applications. Also known as Finish Nuts, Heavy Hex Nuts are used along with bolts – both for strength and for a thick finished look.

Also known as Finish Nuts, Heavy Hex Nuts are used along with bolts – both for strength and for a thick finished look. These are high hardness and low deformation plain washers, punched washers, or flat washers, used as spacers and load distributors.

These are high hardness and low deformation plain washers, punched washers, or flat washers, used as spacers and load distributors. They include carriage bolts; Grade two, five, and eight plow bolts, and more.

They include carriage bolts; Grade two, five, and eight plow bolts, and more. They are heavy-duty fasteners that include weld studs, concrete anchors, and more.

They are heavy-duty fasteners that include weld studs, concrete anchors, and more. Whether you’re going with an all-thread rod or an all-thread stud, they are perfect for heavy-duty projects including manufacturing equipment, motors, and construction.

Whether you’re going with an all-thread rod or an all-thread stud, they are perfect for heavy-duty projects including manufacturing equipment, motors, and construction.