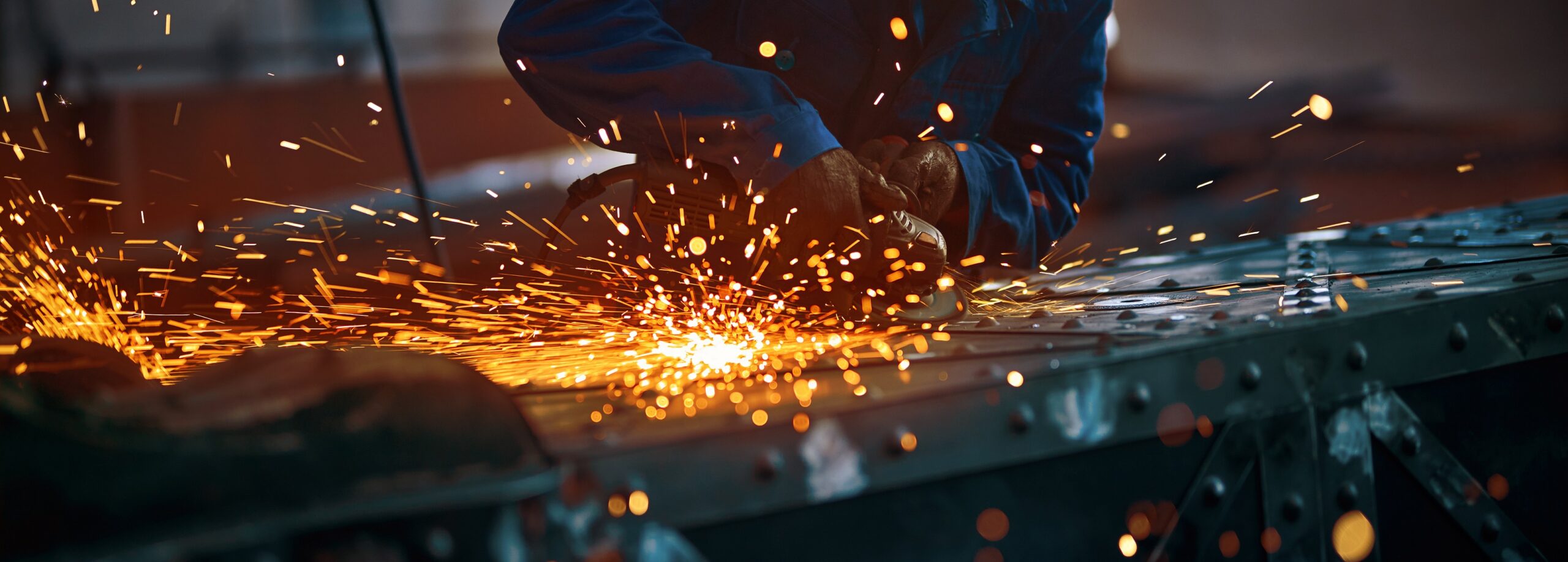

Many mechanic shop owners choose steel buildings for their shops because they offer all advantages of low-rise steel construction methods. A high-quality metal building promises great value— and it delivers on that promise.

There are seven main reasons to use pre-engineered metal buildings for auto shops.

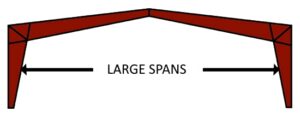

1. SPACE: Our metal auto shop buildings feature clear-span framing which eliminates the need for interior load bearing supports, maximizing workable floor space in your auto shop or mechanical building. Without interior columns, you can more easily manoeuvre vehicles inside, creating drive through functionality. You can customize the height of your building up to 12 meter to easily accommodate car lifts. Also our large spans

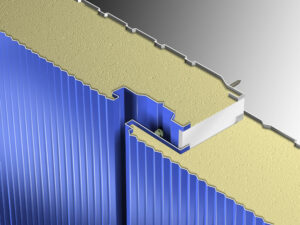

3. NON-COMBUSTIBLE: Steel is not a combustible material therefore frequently used flammable products such as gasoline, oil and etc does not bear high risk for the steel structure. Also our fireproof insulated panels are ideal for workshop roof and walls.

You can configure bays in a variety of sizes and layouts depending on your needs. You can also add an office space or waiting area wherever you’d like. A lot of our clients prefer mezzanines for their offices or storage area in order to save space on the ground floor.

Tekmetsan offers built in mezzanine systems and steel stairs incorporated into the workshop structure.

All commercial building owners, including auto service owners, want a well-built, long-lasting structure that holds the value of their investment. That means they want a TEKMETSAN steel building.

Make your upcoming auto industry construction project a TEKMETSAN steel building. TEKMETSAN auto garages provide years of trouble-free service.

Advances in steel building engineering and manufacturing allow us to custom design a prefab metal building quickly and economically. And with the TEKMETSAN steel building system, later expansion of your auto shop is quick, easy, and inexpensive.

Tekmetsan offers custom design metal workshops for mechanics and repair shop owners. Our long lasting buildings with our excellent customer service offer high value for your money and exceed your expectations.

1 – COST-EFFECTIVE

1 – COST-EFFECTIVE

Using steel for building costs less over time, too. For example:

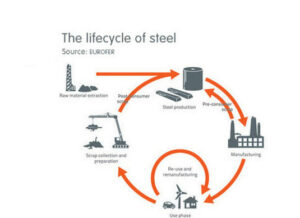

Using steel for building costs less over time, too. For example: Steel buildings also outperform other frame type building in terms of sustainability as well.

Steel buildings also outperform other frame type building in terms of sustainability as well.

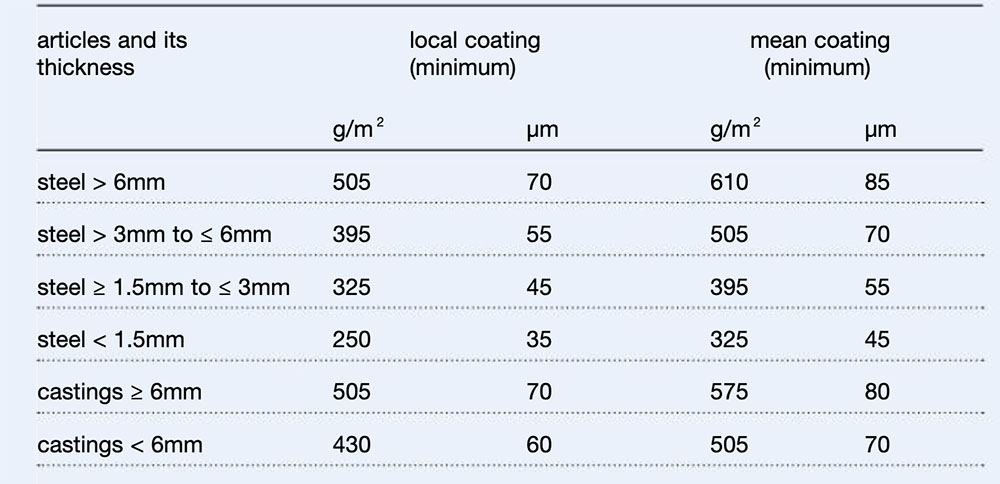

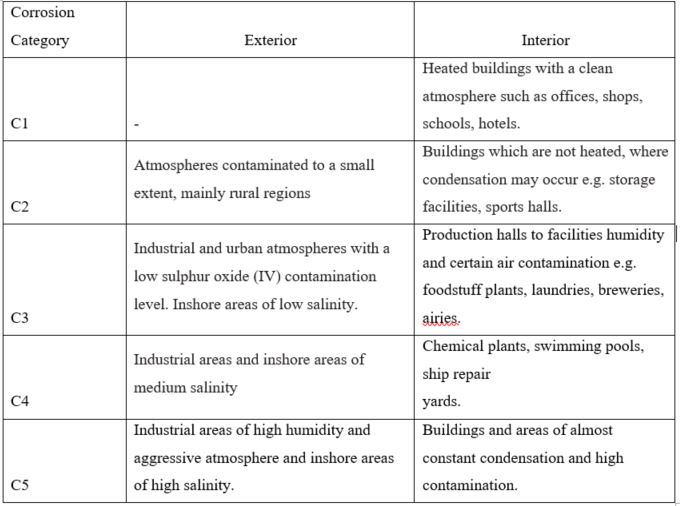

Alkyd paints are the modern descendant of oil paints. Instead of pigment suspended in oil, alkyd paints are typically formed by an alkyd resin dissolved in a thinner. These one-component primers are easy to apply and economical but offer limited

Alkyd paints are the modern descendant of oil paints. Instead of pigment suspended in oil, alkyd paints are typically formed by an alkyd resin dissolved in a thinner. These one-component primers are easy to apply and economical but offer limited Epoxy coatings are typically comprised of an epoxy base and a curing agent. A wide variety of coating properties can be achieved by manipulating either of these components:

Epoxy coatings are typically comprised of an epoxy base and a curing agent. A wide variety of coating properties can be achieved by manipulating either of these components:  Polyurethane coatings are widely used —often as a topcoat— in applications where durability and abrasion resistance are key considerations.

Polyurethane coatings are widely used —often as a topcoat— in applications where durability and abrasion resistance are key considerations.