Custom Metal Frame Building for your specifications

Tekmetsan custom metal buildings are affordable, simple to erect, cost-effective to operate, strong, reliable, and very versatile.

Tekmetsan’s Custom Metal Buildings Offer Amazingly Flexible Designs

With today’s advanced structural steel computer programs, a Tekmetsan frame building is quick and economical to design. You just order the building size that best fits your needs and budget and then let us take care of the rest.

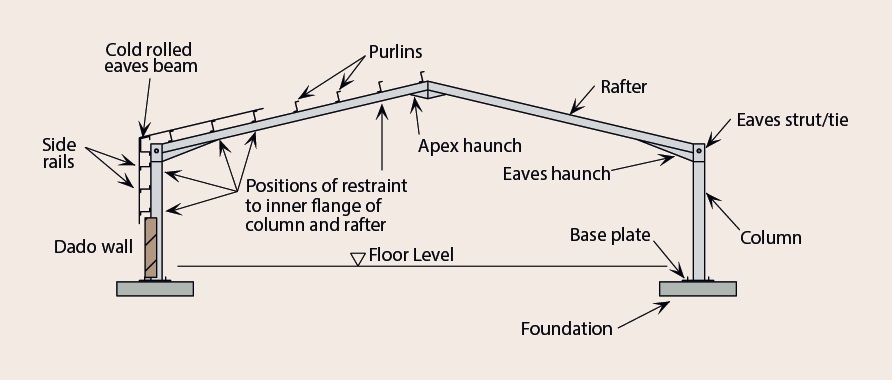

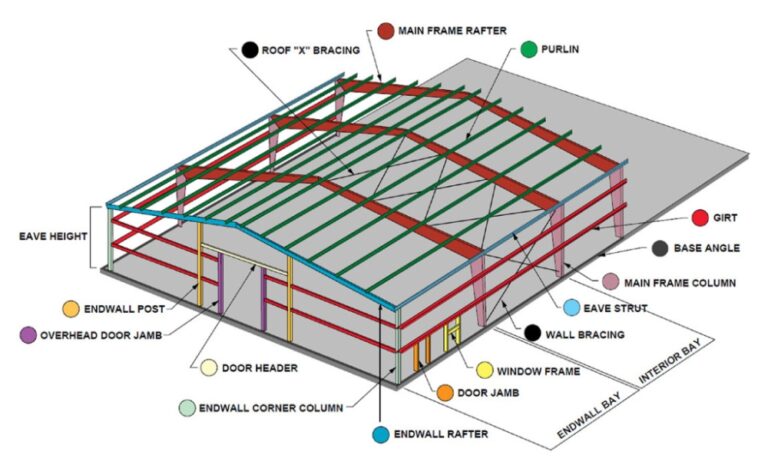

In a Tekmetsan portal frame steel building, columns are typically spaced 6 meters apart.

Our clear span buildings range from 4 meters to 50 meters in width. Adding a single centre column in each frame allows structures as wide as 300 meters.

Only steel is strong enough to handle the loads for such massive dimensions.

Our pre-engineered metal buildings have no length constraints. And all our structural steel buildings extend easily for later expansion.

A Tekmetsan metal framed structure can also be up to 12 meters or more in height.

Also, all Tekmetsan metal frame buildings work on any foundation system, including perimeter footing, pier-and beam, and concrete slab.

Custom Metal Buildings with Remarkably Precise Fabrication

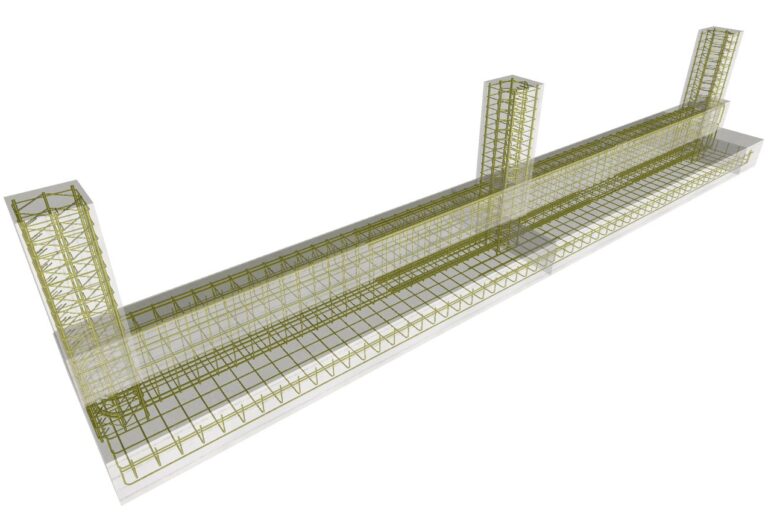

Every Tekmetsan prefab steel frame building is cut, welded, and drilled precisely to exacting industry standards. Tolerances are tight.

When completed, fabricators mark each part for easy identification on the job site.

Since the Tekmetsan steel framing is completely self-supporting, you will enjoy complete freedom for your interior layout.

Our prefab metal buildings also make remodelling a snap. Change wall locations and remodel as you need, without worrying about load-bearing walls.

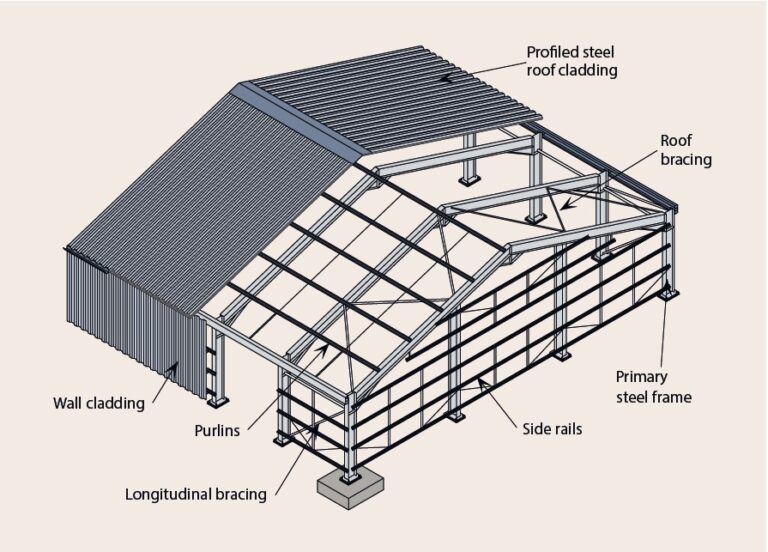

Today’s metal buildings do not look like the old tin barns of past. In fact, there are no limits to the exterior looks available with a Tekmetsan steel building system.

Complete your Tekmetsan metal framed structure with brick, colourful steel panels, decorative block, aluminium panel, glass, stone, wood— or in any combination of these materials.

In addition, you may customize your metal frame building with gutters, energy-saving insulation, canopies and mezzanines, overhangs, parapets, skylights, vents, wall lights, and sturdy entry and overhead doors.

The Countless Uses for Tekmetsan Prefab Metal Buildings

You will find there is a Tekmetsan metal building solution for almost any application. In fact, buyers find that Tekmetsan’s steel building systems adapt perfectly for every use imaginable. For example:

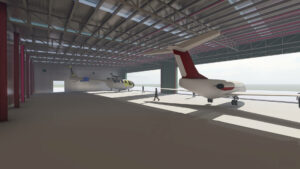

• Helicopter hangars and shade structures

• Automotive, mechanic, and welding shops

• Barns, livestock shades, stables, sheds

• Commercial structures

• Distribution centres and warehouses

• Equestrian riding arenas

• Gymnasiums, sports and recreational centres

• Industrial and manufacturing operations

• Office buildings

• Outdoor pavilions

• Residential storage, RVs and boat garages, multi-purpose garages, and workshops

• Restaurants

• Self-storage operations

• Stores and other retail businesses

• Vehicle dealerships and showrooms

Conclusion

Tekmetsan offers the most versatile metal buildings in the industry today.

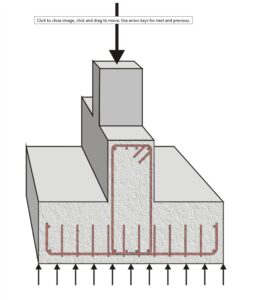

There are two main ways to go about a Pier Foundation. You can either construct your steel building directly on pile or pier, or you can embed the pier in the floating concrete slabs. It looks similar in style to the foundation of decks for the building. In slab foundation type, the top of concrete slab serves the purpose of the floor while in this type the floor is left as dirt or rough gravel.

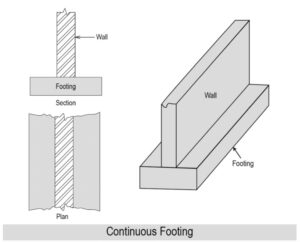

There are two main ways to go about a Pier Foundation. You can either construct your steel building directly on pile or pier, or you can embed the pier in the floating concrete slabs. It looks similar in style to the foundation of decks for the building. In slab foundation type, the top of concrete slab serves the purpose of the floor while in this type the floor is left as dirt or rough gravel. Referred to as standard foundation, this type is used for steel buildings wider than 15 meters. You can also call it a T-wall foundation, perimeter wall foundation or frost wall foundation. The strip which is wider than the width of the perimeter wall provides stability by distributing the load over a larger area. The columns of the steel buildings are

Referred to as standard foundation, this type is used for steel buildings wider than 15 meters. You can also call it a T-wall foundation, perimeter wall foundation or frost wall foundation. The strip which is wider than the width of the perimeter wall provides stability by distributing the load over a larger area. The columns of the steel buildings are