HOW TO INSULATE A METAL BUILDING ?

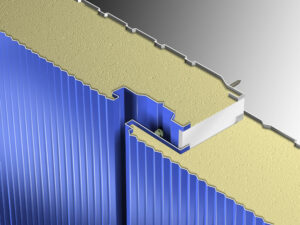

In most applications, the primary feature of thermal insulation material is its ability to reduce heat exchange between a surface and the environment; or between one surface and another surface. The general rule is the lower a material’s thermal conductivity, the greater its ability to insulate for given material thickness and set of conditions.

Before buying an insulation system for your metal building, you need to understand insulation R-value.

At its simplest, insulation R-value indicates the amount of heat flow through an insulation product.

The higher the R-value number, the greater the product’s resistance to heat transference.

The more effectively the insulation works, the greater your energy savings.

However, just buying thicker insulation and stuffing it into a wall does not increase energy efficiency. The more air pockets in insulation, the better the insulation works.

Why Insulation R-Value is so important

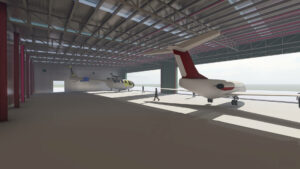

Steel buildings have many benefits over other framing materials. However, steel has one weakness: thermal transference. In an uninsulated metal building, summer heat and winter cold can follow through the framing, affecting interior comfort.

Nevertheless, insulating metal buildings with a first-class insulation system renders steel’s thermal transference moot.

For example, Tekmetsan’s insulation panels breaks heat and cold transfer through the steel, creating a comfortable, cosy inside interior.

Starting with a Tightly Sealed Structure

Even the best metal building insulation is only part of the energy efficiency equation.

If the structure leaks air, it consumes too much energy in spite of a high insulation R-value.

As an organic material, wood framing twists, warps, creeps, and sags with changing humidity. As lumber-framed buildings age, nails start to pull out and loosen, creating air leaks and drafts.

On the other hand, a pre-engineered steel building creates a very tight building envelope.

The steel framing will never move or change in shape. The high-strength bolts and screws used in a TEKMETSAN metal building hold tightly. Consequently, our metal buildings stay tight and draft-free for the lifetime of the structure.

Insulating Metal Buildings during Construction is the Smart Move

Customers sometimes consider cutting corners by eliminating steel building insulation from their order. They think they can add insulation to the building later.

Insulating metal buildings at a later date is possible. However, it is much more labour-intensive to add steel building insulation to an existing structure than to install insulation during construction.

In delayed insulation installation, some of the structure will require disassembly.

In addition, removing and replacing steel panels could cause leaks, if screws are not placed in exactly the same locations.

Conclusion

You need to consider how to insulate a metal building for maximum efficiency right in the early phase of the project design. Tekmetsan steel buildings come with great options of medium and high R values to provide an energy efficient insulated environment for your building.

Using steel for building costs less over time, too. For example:

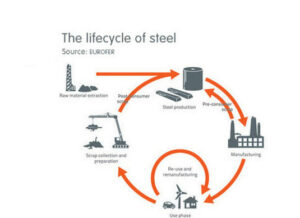

Using steel for building costs less over time, too. For example: Steel buildings also outperform other frame type building in terms of sustainability as well.

Steel buildings also outperform other frame type building in terms of sustainability as well.

Unfortunately we do not offer such product catalogue due to the customized nature of our business. Every TEKMETSAN order is designed and manufactured to the customer’s specific ideas and location.

Unfortunately we do not offer such product catalogue due to the customized nature of our business. Every TEKMETSAN order is designed and manufactured to the customer’s specific ideas and location. You provide us the size of the building you need— length, width, and height. You decide the

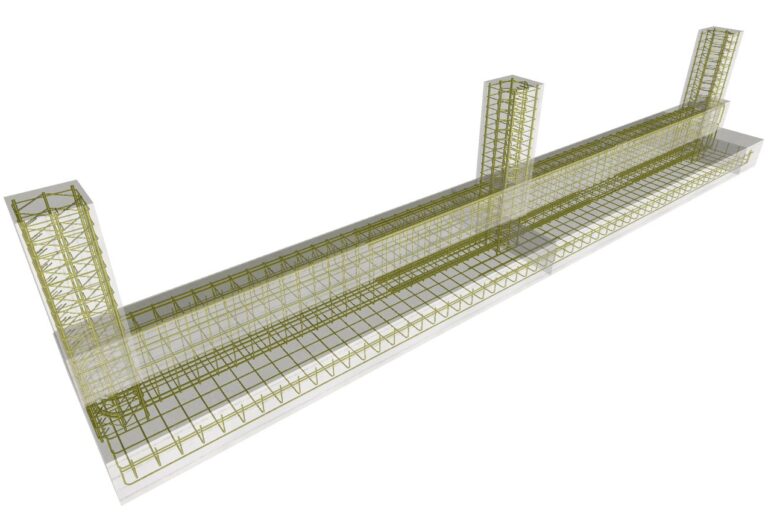

You provide us the size of the building you need— length, width, and height. You decide the  Once you approve the design and place your order, we send detailed fabrication drawings for final confirmation.

Once you approve the design and place your order, we send detailed fabrication drawings for final confirmation.

Heavy hex bolts are characterised by a distinct hexagonal head, making them larger and thicker than standard hex bolts. Heavy hex structural bolts are ideal for steel-to-steel structural connections. They are typically very short. The A325 and A490 specifications are not intended for general applications, including anchor bolts. A449 for A325 and A354 grade BD for A490 are a more suitable choice in these applications.

Heavy hex bolts are characterised by a distinct hexagonal head, making them larger and thicker than standard hex bolts. Heavy hex structural bolts are ideal for steel-to-steel structural connections. They are typically very short. The A325 and A490 specifications are not intended for general applications, including anchor bolts. A449 for A325 and A354 grade BD for A490 are a more suitable choice in these applications. Also known as Finish Nuts, Heavy Hex Nuts are used along with bolts – both for strength and for a thick finished look.

Also known as Finish Nuts, Heavy Hex Nuts are used along with bolts – both for strength and for a thick finished look. These are high hardness and low deformation plain washers, punched washers, or flat washers, used as spacers and load distributors.

These are high hardness and low deformation plain washers, punched washers, or flat washers, used as spacers and load distributors. They include carriage bolts; Grade two, five, and eight plow bolts, and more.

They include carriage bolts; Grade two, five, and eight plow bolts, and more. They are heavy-duty fasteners that include weld studs, concrete anchors, and more.

They are heavy-duty fasteners that include weld studs, concrete anchors, and more. Whether you’re going with an all-thread rod or an all-thread stud, they are perfect for heavy-duty projects including manufacturing equipment, motors, and construction.

Whether you’re going with an all-thread rod or an all-thread stud, they are perfect for heavy-duty projects including manufacturing equipment, motors, and construction.

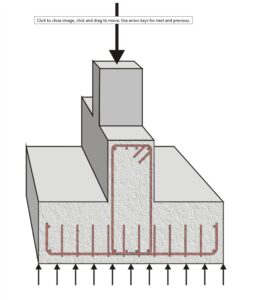

There are two main ways to go about a Pier Foundation. You can either construct your steel building directly on pile or pier, or you can embed the pier in the floating concrete slabs. It looks similar in style to the foundation of decks for the building. In slab foundation type, the top of concrete slab serves the purpose of the floor while in this type the floor is left as dirt or rough gravel.

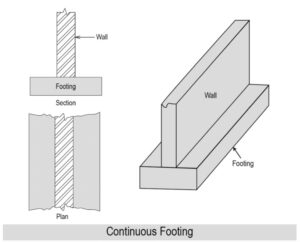

There are two main ways to go about a Pier Foundation. You can either construct your steel building directly on pile or pier, or you can embed the pier in the floating concrete slabs. It looks similar in style to the foundation of decks for the building. In slab foundation type, the top of concrete slab serves the purpose of the floor while in this type the floor is left as dirt or rough gravel. Referred to as standard foundation, this type is used for steel buildings wider than 15 meters. You can also call it a T-wall foundation, perimeter wall foundation or frost wall foundation. The strip which is wider than the width of the perimeter wall provides stability by distributing the load over a larger area. The columns of the steel buildings are

Referred to as standard foundation, this type is used for steel buildings wider than 15 meters. You can also call it a T-wall foundation, perimeter wall foundation or frost wall foundation. The strip which is wider than the width of the perimeter wall provides stability by distributing the load over a larger area. The columns of the steel buildings are