5 Factors to choose your steel supplier

Steel is a hugely popular metal used in residential, commercial or large construction projects. With many options, it can be overwhelming to select a steel fabrication supplier for the first time. It is important to do your research and perform due diligence on a company before signing a contract however, this is not always possible through online sources.

Asking the right questions of your potential supplier is important and sometimes, the best way to research their credentials.

If you’ve never worked with a metal supplier before, consider the following factors before choosing one:

1. Product and Fabrication Range

Choose a supplier with a wide product range so that you can have all your steel requirements met instead of sourcing them from different companies, and the inherent planning and delivery problems that comes with this.

Tekmetsan is a one stop shop for all your steel structure needs.

We have an experienced in-house design department and sophisticated fabrication workshop to meet all your expectations.

2. Design Capabilities and Technology

The best manufacturers of steel structures have experienced designers who will create an individual design according to the customer’s guidelines.

The best manufacturers of steel structures have experienced designers who will create an individual design according to the customer’s guidelines.

They are not afraid of making changes at various stages and they are able to incorporate thought future modifications, e.g. additional features, expansion, a changed layout, or even a transfer of the steel building to another location.

Our great design team and fabrication capabilities enable us to offer highly customized solutions for changing client needs.

3. Experience & References

A company that has been on the market for a long time is a safe choice. Make sure that the steel manufacturer you choose meets all your expectations, check and look at the projects that have been delivered by the company to be sure.

A company that has been on the market for a long time is a safe choice. Make sure that the steel manufacturer you choose meets all your expectations, check and look at the projects that have been delivered by the company to be sure.

If there are many you can be confident that the company has the ability to deliver steel halls of all kinds.

The best manufacturers list interesting projects on their websites. Tekmetsan has a broad range of project references all around the world.

4. Production Quality

Before selecting a supplier, make sure that they do not provide substandard and poor-quality materials and tools. To ensure that this does not happen, look through the history of a before choosing them.

Before selecting a supplier, make sure that they do not provide substandard and poor-quality materials and tools. To ensure that this does not happen, look through the history of a before choosing them.

If the supplier is recognized for good quality products, then you can rest assured that they would offer reliable products.

Tekmetsan production systems is certified by leading German intuition Tuv-Nord on a yearly basis and all our products are CE certified.

5. Customer Support and Reliability

At Tekmetsan, we work hand in hand with clients to understand their ideas, enabling us to deliver the best possible service, on time, on budget and with the safety of everyone in mind.

At Tekmetsan, we work hand in hand with clients to understand their ideas, enabling us to deliver the best possible service, on time, on budget and with the safety of everyone in mind.

As we have been in operation for over 10 years we have a high returning customer base from both small private clients to leading brands.

With our excellent customer service and transparent quotations, you can rest assured we have your best interests at heart in saving you money on your project.

Customer service is like steel—it’s ultimately the foundation of all we do. From the moment you contact our customer service representatives, you will be expertly guided through the design of a structure tailored to your exact specifications, right down to the foundation, trim and paint.

When you ask for pricing on a building or components, you receive a quote with an easy-to-follow detailed description. We follow up with a materials list that accompanies the delivery of your building. Our customer service department continues to assist you after your building has been delivered.

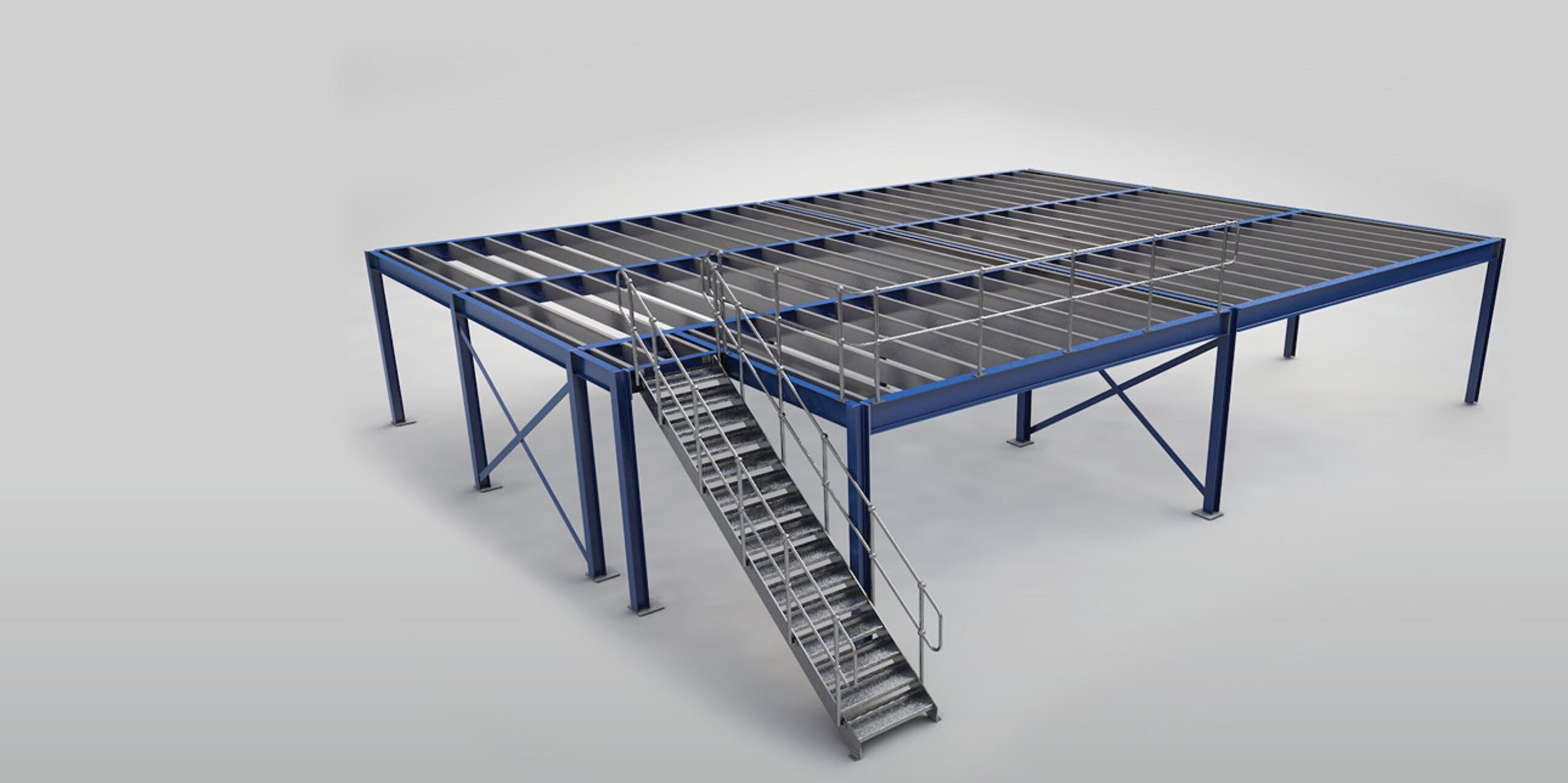

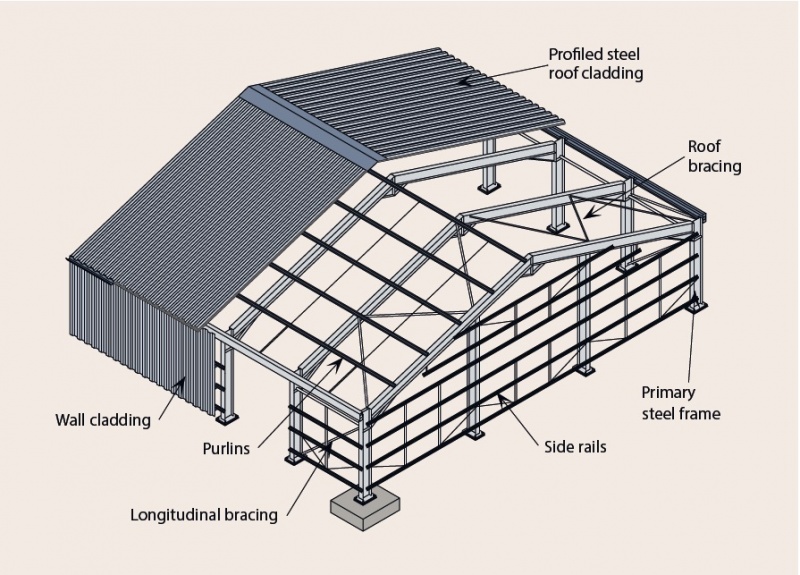

The greatest benefit of structural steel is allowing bigger column spacing. Column spacing can increase up to 8 meters without compromising the dead and live loads on the mezzanine floor.

The greatest benefit of structural steel is allowing bigger column spacing. Column spacing can increase up to 8 meters without compromising the dead and live loads on the mezzanine floor.

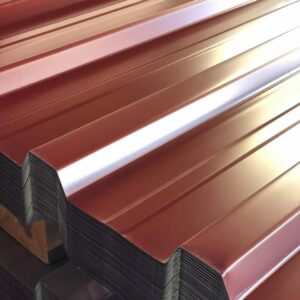

It is the combination of formability, flatness, stability and weather resistance that characterises this façade panel as an excellent option for a building façade.

It is the combination of formability, flatness, stability and weather resistance that characterises this façade panel as an excellent option for a building façade. A modern solution for both residential and commercial construction projects, sandwich panels are composite elements that can be used to build floors, walls, and roofs. Also known as insulated panels, sandwich panels consist of an

A modern solution for both residential and commercial construction projects, sandwich panels are composite elements that can be used to build floors, walls, and roofs. Also known as insulated panels, sandwich panels consist of an  Tekmetsan offer a self-supporting steel profiled single skin cladding system suitable for both roof and walls. The profiles consist of a coated steel outer sheet rolled to several cladding profiles which can be used to form roofs and for wall cladding.

Tekmetsan offer a self-supporting steel profiled single skin cladding system suitable for both roof and walls. The profiles consist of a coated steel outer sheet rolled to several cladding profiles which can be used to form roofs and for wall cladding.  Cladding a building with perforated metal is a very effective way to enliven the facade of what would otherwise be a simple cubed structure. …

Cladding a building with perforated metal is a very effective way to enliven the facade of what would otherwise be a simple cubed structure. …  When exposed to atmospheric conditions, Weathering Steel undergoes an oxidisation process, where protective layers develop on the material’s surface. These layers contribute to performance and create the metal’s rust coloured architectural aesthetic.

When exposed to atmospheric conditions, Weathering Steel undergoes an oxidisation process, where protective layers develop on the material’s surface. These layers contribute to performance and create the metal’s rust coloured architectural aesthetic.

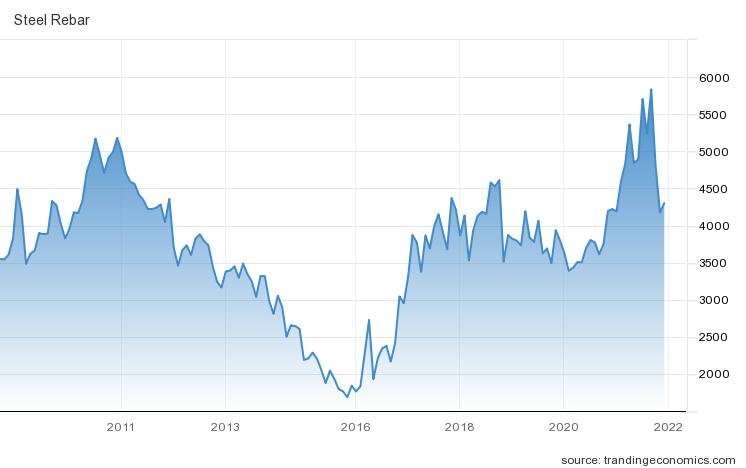

• In the past, price increases were most often forecast with ample time for owners to make smart decisions in advance on when and how to move forward with their projects, as of lately the volatile market is experiencing literally overnight price updates that makes it complicated for decision makers to anticipate this as the new normal and be ready to act in order to protect their

• In the past, price increases were most often forecast with ample time for owners to make smart decisions in advance on when and how to move forward with their projects, as of lately the volatile market is experiencing literally overnight price updates that makes it complicated for decision makers to anticipate this as the new normal and be ready to act in order to protect their

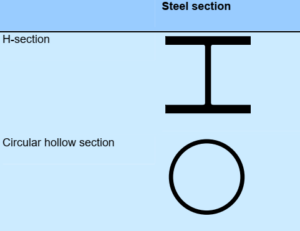

The main purpose of the columns is to transfer the vertical loads to the

The main purpose of the columns is to transfer the vertical loads to the

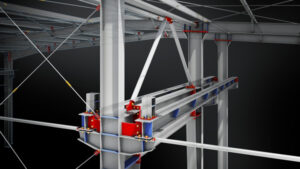

A bracing system is a secondary but essential part of a steel structure. A bracing system serves to stabilize the main girders during construction, to contribute to the distribution of load effects and to provide restraint to compression flanges or chords where they would otherwise be free to buckle laterally.

A bracing system is a secondary but essential part of a steel structure. A bracing system serves to stabilize the main girders during construction, to contribute to the distribution of load effects and to provide restraint to compression flanges or chords where they would otherwise be free to buckle laterally.

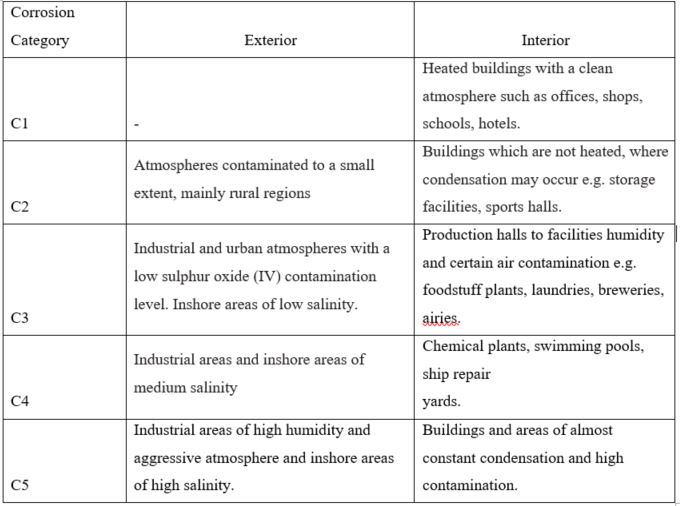

Alkyd paints are the modern descendant of oil paints. Instead of pigment suspended in oil, alkyd paints are typically formed by an alkyd resin dissolved in a thinner. These one-component primers are easy to apply and economical but offer limited

Alkyd paints are the modern descendant of oil paints. Instead of pigment suspended in oil, alkyd paints are typically formed by an alkyd resin dissolved in a thinner. These one-component primers are easy to apply and economical but offer limited Epoxy coatings are typically comprised of an epoxy base and a curing agent. A wide variety of coating properties can be achieved by manipulating either of these components:

Epoxy coatings are typically comprised of an epoxy base and a curing agent. A wide variety of coating properties can be achieved by manipulating either of these components:  Polyurethane coatings are widely used —often as a topcoat— in applications where durability and abrasion resistance are key considerations.

Polyurethane coatings are widely used —often as a topcoat— in applications where durability and abrasion resistance are key considerations.

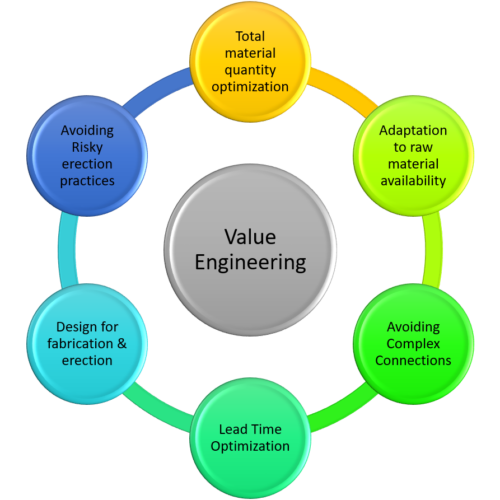

Some value engineering activities that we are constantly checking are;

Some value engineering activities that we are constantly checking are;