In our fast-moving world, steel buildings are offering great value to consumers.

Their large span design, versatility, and fast erection make them the ideal choice for the people investing in buildings for workshops, residential buildings, commercial and industrial space and many more other building types.

The versatility is only limited by your imagination during the design process.

The versatility is only limited by your imagination during the design process.

The accuracy of the manufacturing of steel buildings makes erecting a steel building quick and safe; therefore, occupancy can be in weeks rather than months.

Much like any construction, careful attention must be given to the below considerations for standing a building.

1. A good packed flat excavated surface is the start for the whole process. A groundwork contractor may help you to

2. The concrete must be poured correctly with a flat uniform surface. Dips or valleys will cause you problems in the later stage if they are not dealt right after the pouring.

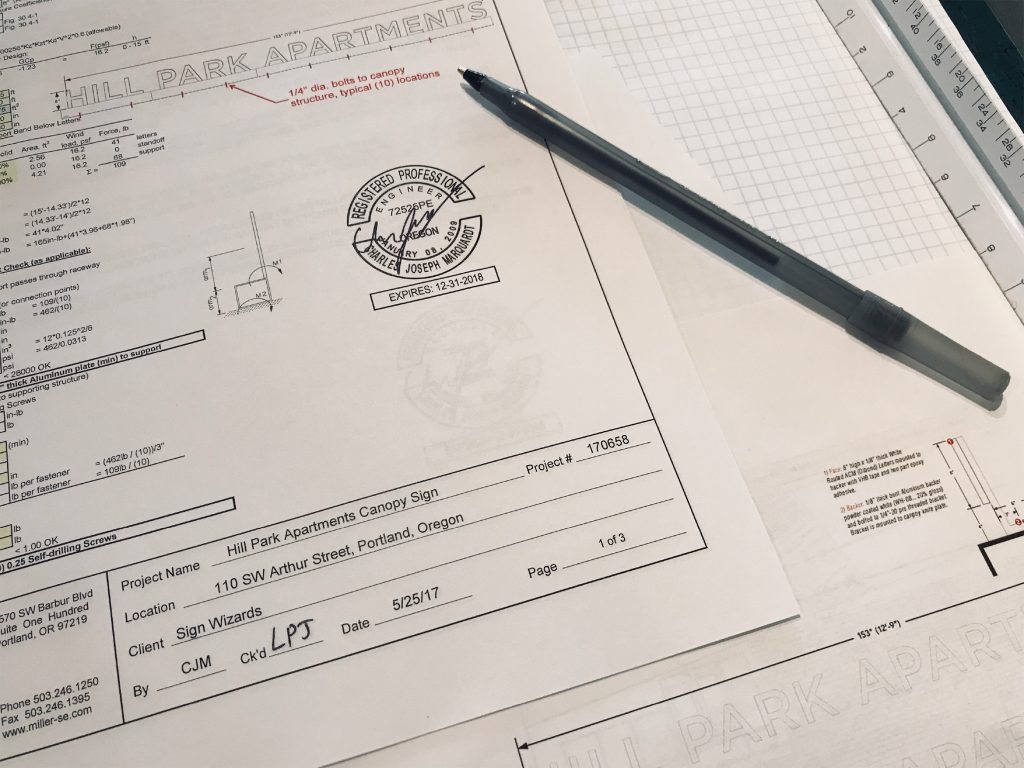

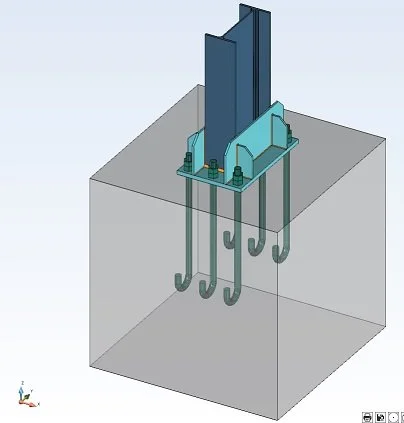

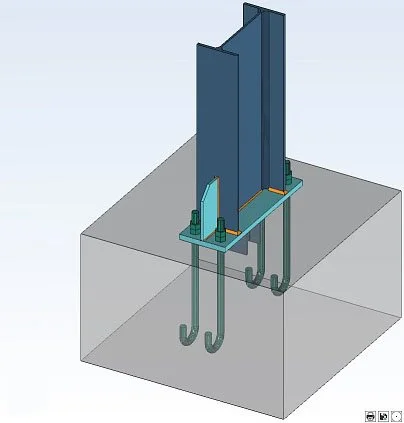

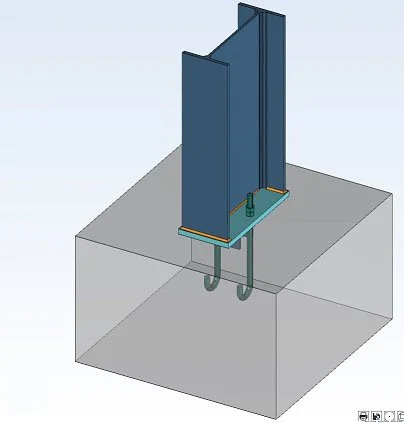

3. The anchor bolts must be set and squared off to insure fit for the building columns. The blueprints provided by Tekmetsan is your guide in the anchor bolt instalment. We always recommend you to consult a land surveyor whilst placing the anchor bolts.

4. An erection must be performed according to the manufacturer’s assembly requirements. There should not be corrections needed if all phases of this project are complying with the stamped prints supplied.

5. An accredited building manufacturer should be assigned. The building can only be erected in a safe and timely manner with no delays if the manufacturer supplies good quality and correctly manufactured parts.

This is a frequently asked question, and the answer is dependent on several factors.

There are certain things that cannot be counted on when an erector gives you a quote to build your steel structure.

• Is the foundation ready and anchor bolts correctly placed?

• Weather forecast- Any rainy or snow days ahead

• All the steel parts are ready on jobsite.

• Any damaged or faulty part?

• Access of the crew and lifting equipment to the jobsite is possible

When an erector is scheduling their works, they have to take into account the equipment and crew required at the job site, how long it should take to complete various stages of erection, and making sure they can get to their next scheduled appointment on time.

When the next job is scheduled and any of the above problems happen, the equipment and crew become idle which will cause a financial burden either to erector, the customer or both. Crews have to wait and reschedule equipment and manpower to return for better weather or new parts. Also delays may affect the schedules of the next job of the erector causing them losing their next job. It is very important to us at Tekmetsan that the erectors have all they need. And also all parts are correct and accounted for. We provide detailed assembly drawings and part drawings to make the job of the erector as easy as possible. The easier and faster the building goes up is a compliment to us and also a value for our customers.

When the next job is scheduled and any of the above problems happen, the equipment and crew become idle which will cause a financial burden either to erector, the customer or both. Crews have to wait and reschedule equipment and manpower to return for better weather or new parts. Also delays may affect the schedules of the next job of the erector causing them losing their next job. It is very important to us at Tekmetsan that the erectors have all they need. And also all parts are correct and accounted for. We provide detailed assembly drawings and part drawings to make the job of the erector as easy as possible. The easier and faster the building goes up is a compliment to us and also a value for our customers.

• Foundation: anchor bolts are placed correctly and levelled

• Access to the jobsite for delivery of the materials, equipment and crew

• Clear job site around the foundation so materials can be separated and stacked as needed

• Equipment to unload the truck and manpower to inventory bundles and crates.

For a successful project execution and compliance with the local building regulations, the building manufacturer is responsible only for the structural design of the metal building system it sells to the building.

For a successful project execution and compliance with the local building regulations, the building manufacturer is responsible only for the structural design of the metal building system it sells to the building.

6. Weld Quality Management

6. Weld Quality Management

2.

2.  With the flexibility metal buildings offer, you’re free to customize the interior of your automotive repair building with functionality & efficiency in mind.

With the flexibility metal buildings offer, you’re free to customize the interior of your automotive repair building with functionality & efficiency in mind.