Steel Fabrication Process

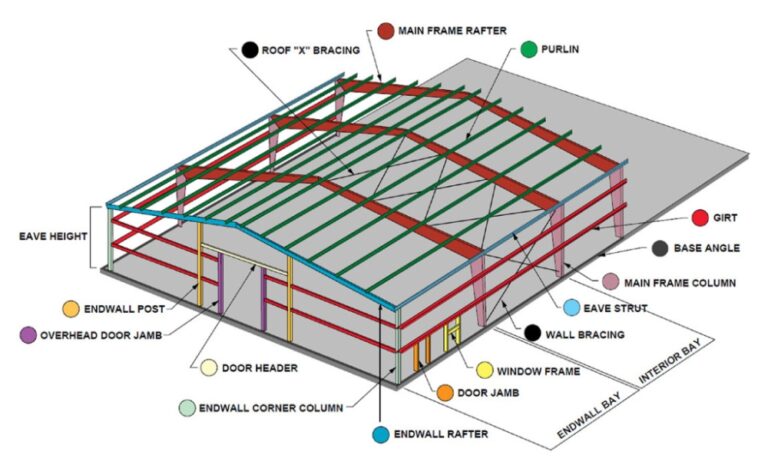

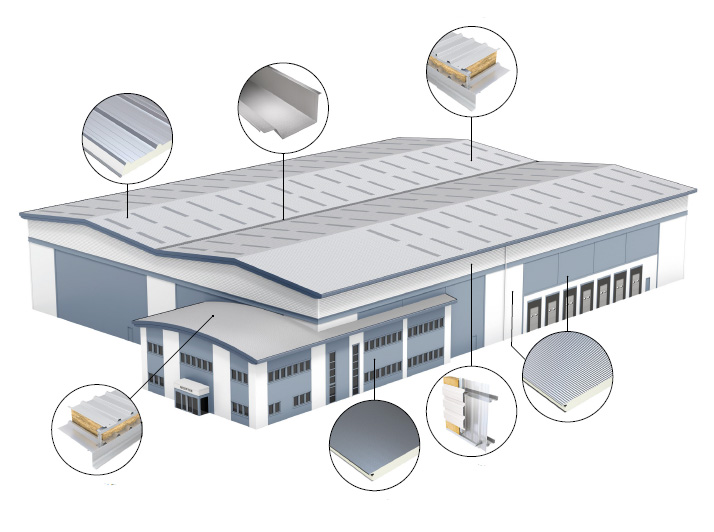

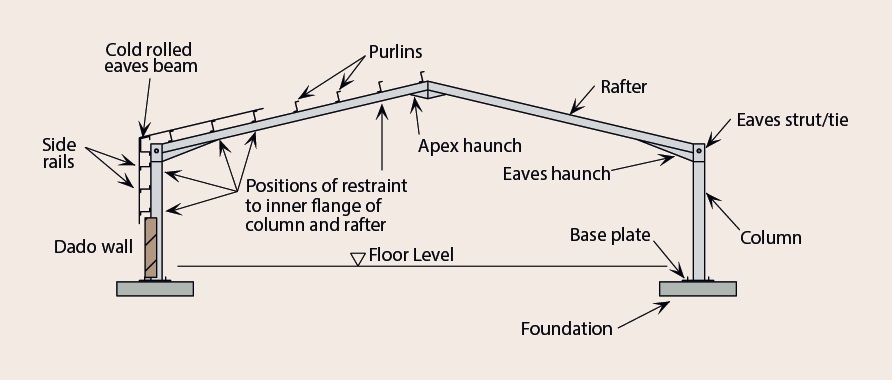

Fabrication is the process used to manufacture steelwork components that will, when assembled and joined, form a complete frame or structure.

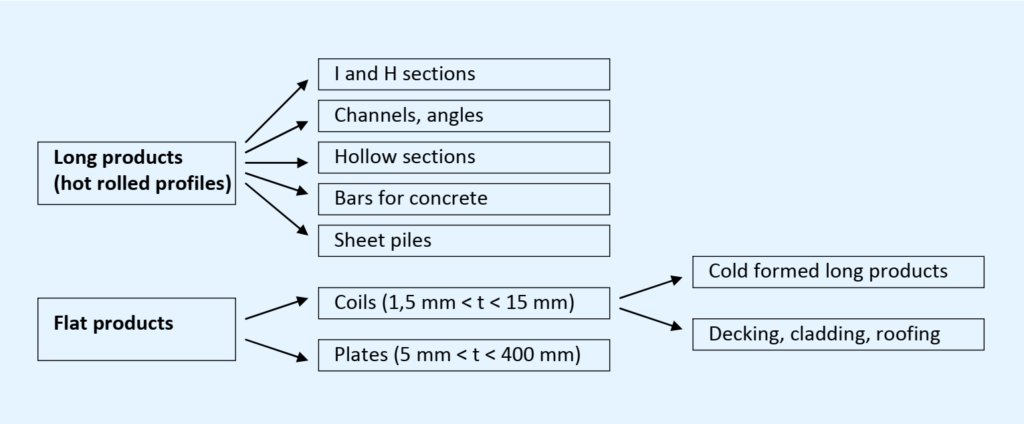

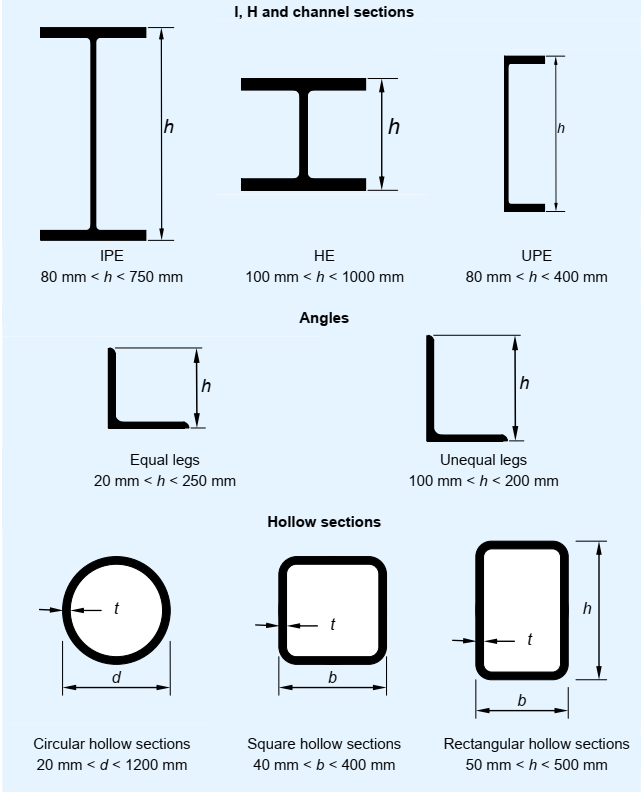

At Tekmetsan, we usually use readily available standard sections that are purchased from the steel mills, together with such items as protective paints and bolts from other specialist suppliers.

Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of our production.

Steel Fabrication Steps

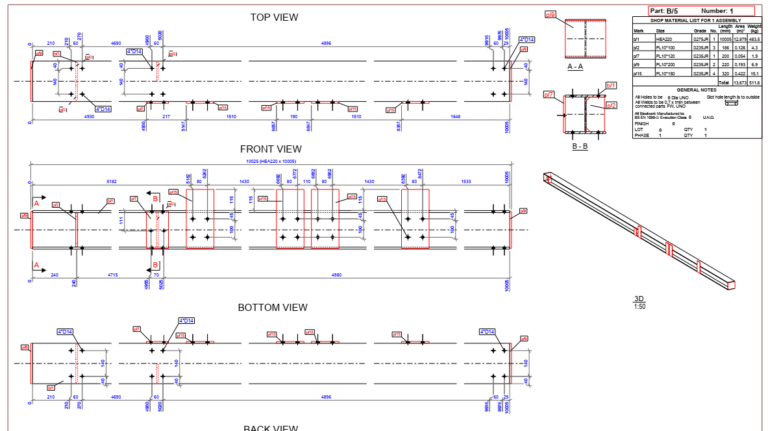

While the architect creates the blueprint, a fabricator evaluates the steps with steelwork and recommend alterations that could be done to the shop drawing. And then, approval or rejection of these recommendations is done by the architect.

While the architect creates the blueprint, a fabricator evaluates the steps with steelwork and recommend alterations that could be done to the shop drawing. And then, approval or rejection of these recommendations is done by the architect.

At Tekmetsan, our engineers and draftsmen work on the approved blueprint to create the details of the all steel parts that form the steel structure. These drawings will be used while manufacturing the components. For every individual shop drawing that is created, the below-mentioned aspects get the undivided attention:

2. Cutting, Bending, Drilling

Cutting is the first part of structural steel fabrication. High-grade steel needs to be cut by cropping or sawing using different tools like sawing and drilling lines, laser cutters, plasma cutters, or water jets etc.

Cutting is the first part of structural steel fabrication. High-grade steel needs to be cut by cropping or sawing using different tools like sawing and drilling lines, laser cutters, plasma cutters, or water jets etc.

The methods typically employed are sawing (cold sawing or band sawing), burning and shearing. All these tasks are performed under a closed manufacturing factory and all required safety measures are taken for these processes.

3. Welding & Assembly

Steel sections are assembled here to make complete structures. After cutting and forming of steel components are done, then the welding process begins to assemble it into a complete structure. Structural welding has its own set of codes, blueprints, and types of weld joints.

Steel sections are assembled here to make complete structures. After cutting and forming of steel components are done, then the welding process begins to assemble it into a complete structure. Structural welding has its own set of codes, blueprints, and types of weld joints.

The process of welding involves the joining of two separate metal parts. The parts used in a welding application could be sheets, sections, bars or shapes. Welding is achievable through numerous methods and tool types. Often, a weld is achieved through the application of heat along the points where the two pieces are meant to be joined.

All the metal surfaces are cleaned by sandblasting or shot blasting before the paint application. Upon the request of the clients, Tekmetsan also offers hot dip galvanization coating to its clientele, however hot dip galvanization works are outsourced to specialized galvanization subcontractors.

All the metal surfaces are cleaned by sandblasting or shot blasting before the paint application. Upon the request of the clients, Tekmetsan also offers hot dip galvanization coating to its clientele, however hot dip galvanization works are outsourced to specialized galvanization subcontractors.

Based on the paint selection of the customer, all painting works are performed in climate controlled environment according to the international standards.

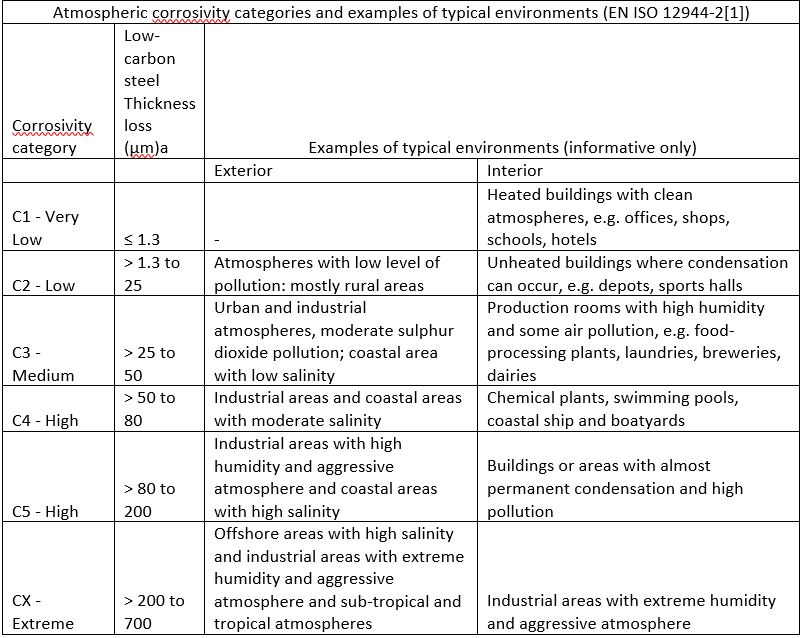

Tekmetsan offers various types of paint coating for different levels of environments.

5. Packaging and Shipment

All the products are marked, packed and palletized and stored in the finish product warehouse. Tekmetsan uses overhead cranes and mobile high-up for the loading. We are able to load all means of transportation vehicles.

All the products are marked, packed and palletized and stored in the finish product warehouse. Tekmetsan uses overhead cranes and mobile high-up for the loading. We are able to load all means of transportation vehicles.

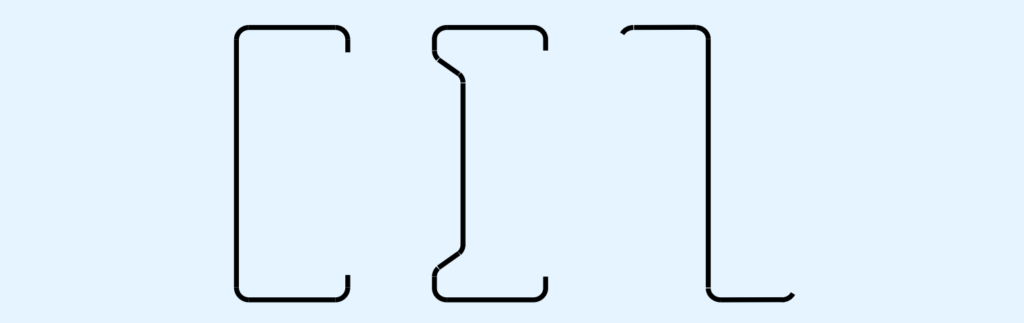

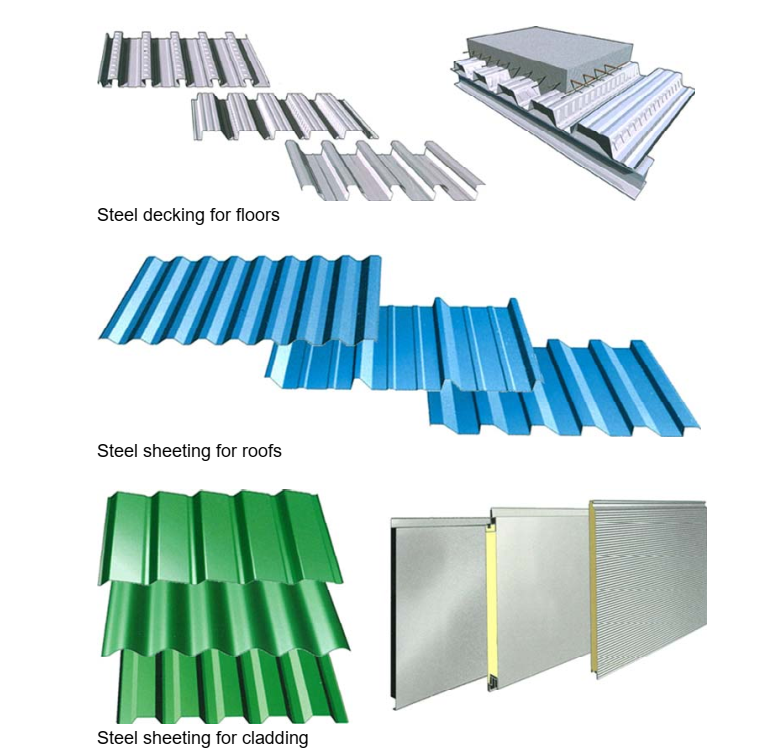

Sheet steel runs through a progressive series of rollers that shapes the flat material into a specific cross-sectional profile that is strong and durable. After cutting to length, appropriately bundled and crated, the finished product is ready for delivery.

Sheet steel runs through a progressive series of rollers that shapes the flat material into a specific cross-sectional profile that is strong and durable. After cutting to length, appropriately bundled and crated, the finished product is ready for delivery.

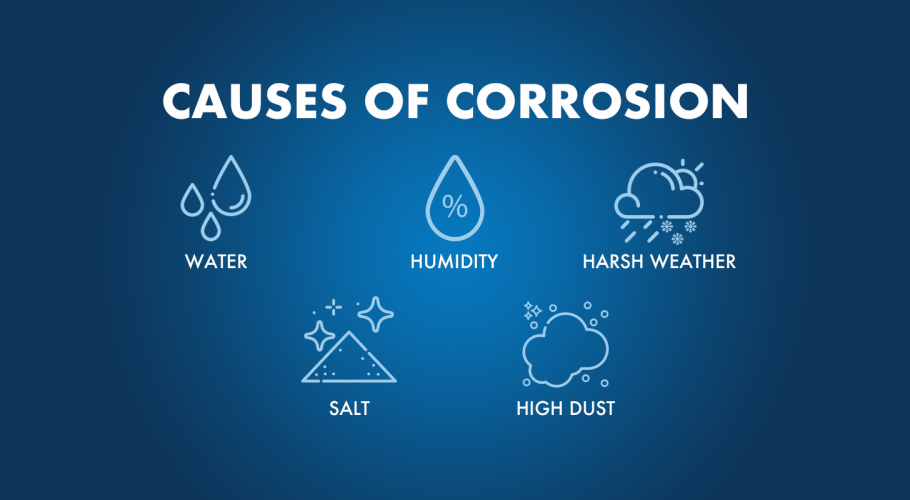

Corrosion must be considered early in the design of steel structures. If left unprotected in corrosive environments, steel structures are liable to corrosion that can be both costly and put lives in danger.

Corrosion must be considered early in the design of steel structures. If left unprotected in corrosive environments, steel structures are liable to corrosion that can be both costly and put lives in danger.

Experienced technical sales of Tekmetsan will help you in determining what kind of corrosion class your structure falls. After identifying the corrosion class, our experts will offer you the appropriate

Experienced technical sales of Tekmetsan will help you in determining what kind of corrosion class your structure falls. After identifying the corrosion class, our experts will offer you the appropriate

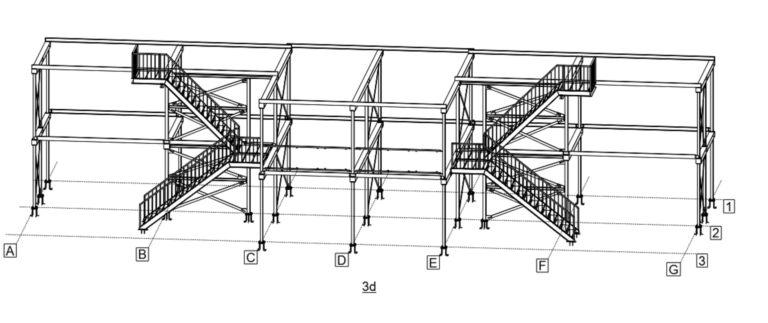

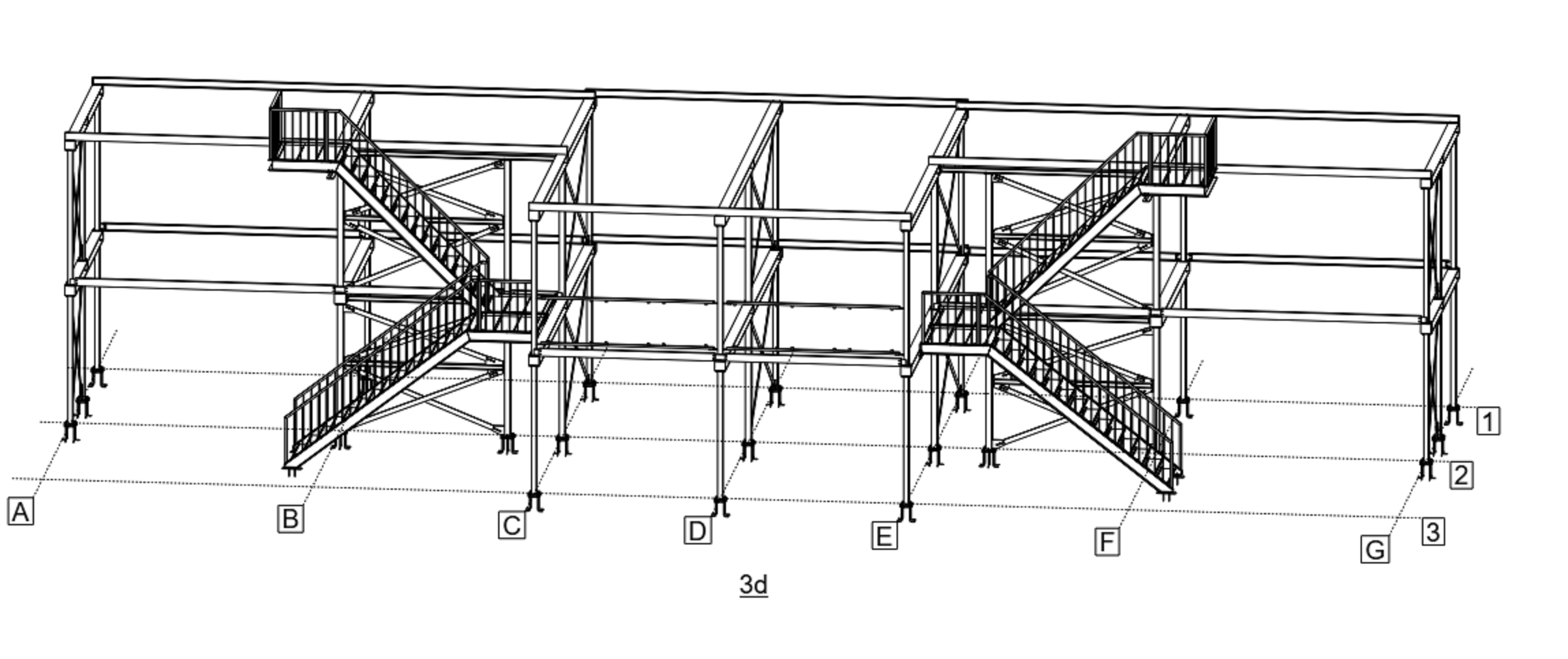

Modular, permanent, code-compliant, industrial staircases (cage, cat ladders) designed to meet the access requirements of industrial applications.

Modular, permanent, code-compliant, industrial staircases (cage, cat ladders) designed to meet the access requirements of industrial applications. Tekmetsan fabricates

Tekmetsan fabricates

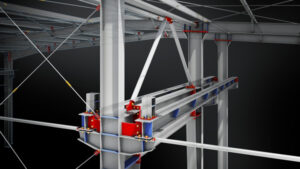

Structural steel detailing entails the development of comprehensive drawings for our fabrication similar as plans, estimates, and other necessary reports and activities. There are two sorts of drawings we used in this process: shop drawings and erection drawings.

Structural steel detailing entails the development of comprehensive drawings for our fabrication similar as plans, estimates, and other necessary reports and activities. There are two sorts of drawings we used in this process: shop drawings and erection drawings.